Shot Blasting

Why We Do It?

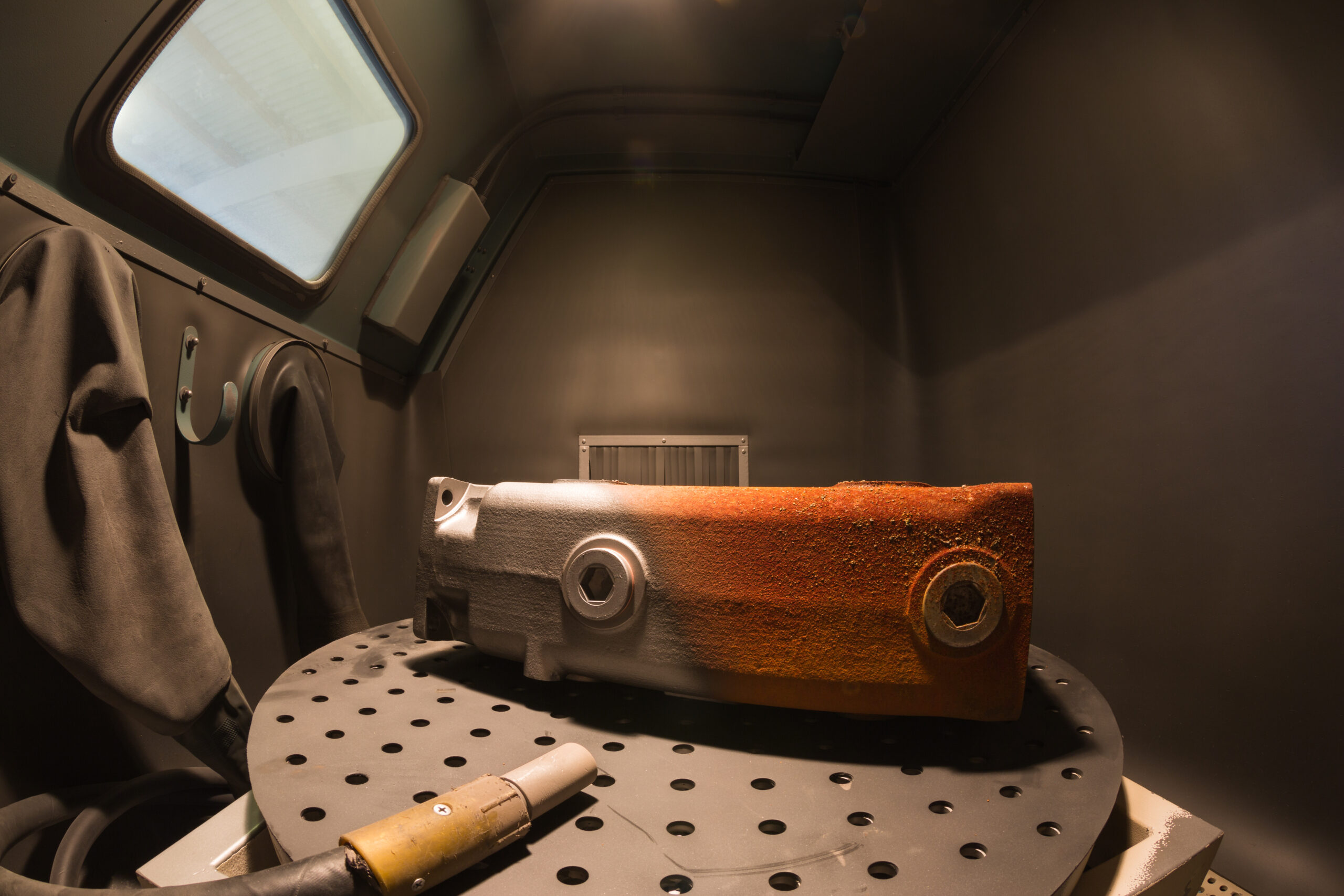

Shot blasting is a technological process of removing various impurities such as the removal of paint, rust or other surface imperfections from most metal structures or different surfaces. This process can restore metalwork as close to its original condition as possible, increasing its lifespan and aesthetic appeal.

Shot Blasting is used for a surface protection and also prior-preparation of surfaces prior to further processing, such as Welding or Powder Coating, etc.

Shot Blasting can be used in different industries, such as: automotive industry, metal-manufacturing industry, foundry, aviation industry, shipbuilding, production of various welded structures and also in production of various tanks, silos, pipelines, chassis, etc.

How We Do It?

Shot blasting is the process of propelling steel shot via compressed air.

We use blast media and blasting abrasives to provide surface texturing and preparation, etching, finishing and degreasing

Shot blasting is a method used to clean, strengthen or polish metal and is typically done in a blast room. Cast steel shot or steel grit is used to clean and prepare the surface before the powder coating process can begin.